|

DRILLING OF DEEP TUBEWELLS

The Company assures successful drilling and construction of deep tubewells down to 600 m (2000 ft) in all kinds of hydro-geological environ to obtain optimal yield. In a record time of 107 days four (4) tubewells of 1100 ft. depth were installed at Defence Cantonment Ambala, a known problematic area. Successfull tubewells have also been installed in Beet Area of Punjab where water table is 75 to 165 mts. below the land surface. The company has also introduced open hole drilling technology in bouldery formations with the help of tubular bit (Japanese type). With the adoption of this latest technology, now it has become possible to drill boreholes with precussion rig down to 300 metres depth which was not possible with conventional precussion technology(Case borehole).

|

|

DRILLING INNOVATIONS

Due to increased demand for Water coupled with the need to tackle the problem of exhausted/ overexploited shallow aquifer potential, It was a breakthrough in drilling and tubewell construction technology in India when the Company introduced Reverse circulation Rig of 2000 ft. depth/32" diameter capacity for tapping deeper virgin aquifers and compatible compressor of 550 CFM @ 600 PSI capacity for effective well development. With this combination, the company assures successful construction of tubewells upto 2000 ft. depth in alluvial areas to obtain optimal yield. The Overdevelopment Pumps and Compressors of varying capacity are available to suit completion of tubewells in different areas. The company is fully equipped with a workshop for all kind of machine shop jobs, slot cutting machines, welding sets etc.

|

|

DEVELOPMENT OF TUBEWELLS

The company is equipped with 1400 to 450 CFM and 150 to 600 PSI capacity compressors for development of tubewells. The 550 CFM at 600 PSI, compressor has been introduced for the first time in India, in tubewell industry for quick and effective development of tubewells of depth upto 1500 ft. by direct lowering of air line. In addition the tubewells are developed by submerrsible pumps to make the discharge silt free. Step draw down test is conducted to determine operational discharge and well efficiency.Last year new screw air compressor of 1400 CFM @ 350 PSI was also introduced for the first time in drilling industry.

|

|

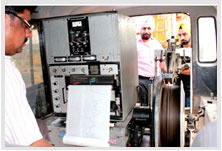

ELECTRICAL LOGGING

To decipher potential water bearing zones and quality of formation water, the logging of bore holes is taken up with the electronic logger by the company which can log upto 600m depth. This helps in designing the well scientifically and getting long trouble free service for the tubewells.

|

|